SEAM ROOF

In the area of roofing production, we present falcané roof panels, a modern solution and at the same time a simple and quick alternative to traditional roofs. Falcaný plech is suitable for covering or..

The total height: 25 mm

Product thickness: 0.45 mm

Coating: gloss

Producing : BILKA

Guarantee: 10 years

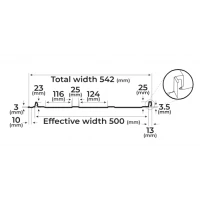

Overall width: 560 mm

Effective coverage width: 550 mm

In the area of roofing production, we present falcané roof panels, a modern solution and at the same time a simple and quick alternative to traditional roofs. Falcaný plech is suitable for covering or..

The total height: 25 mm

Product thickness: 0.45 mm

Coating: Мат

Producing : BILKA

Guarantee: 10 years

Overall width: 560 mm

Effective coverage width: 550 mm

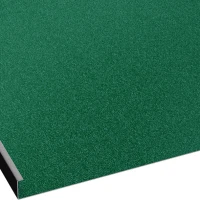

In the area of roofing production, we present falcané roof panels, a modern solution and at the same time a simple and quick alternative to traditional roofs. Falcaný plech is suitable for covering or..

The total height: 25 mm

Product thickness: 0,5 mm

Coating: Grande Mat

Producing : BILKA

Guarantee: 10 years

Overall width: 560 mm

Effective coverage width: 550 mm

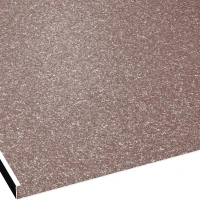

In the area of roofing production, we present falcané roof panels, a modern solution and at the same time a simple and quick alternative to traditional roofs. Falcaný plech is suitable for covering or..

The total height: 25 mm

Product thickness: 0,6 mm

Coating: Double-sided painted гланц

Producing : BILKA

Guarantee: 30 years

Overall width: 560 mm

Effective coverage width: 550 mm

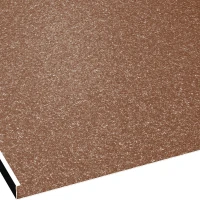

In the area of roofing production, we present falcané roof panels, a modern solution and at the same time a simple and quick alternative to traditional roofs. Falcaný plech is suitable for covering or..

The total height: 25 mm

Product thickness: 0,6 mm

Coating: Matt painted on both sides

Producing : BILKA

Guarantee: 30 years

Overall width: 560 mm

Effective coverage width: 550 mm

..

Product thickness: 0.45 mm

Coating: Gloos

Producing : ROOFER

Guarantee: 10 years

..

Product thickness: 0.45 mm

Coating: Gloos

Producing : ROOFER

Guarantee: 10 years

It is used for hermetické hrebenové roof elements hydroisolace and prevention protekání vody under falcované panels. It is used on střechy s jedním sklonem...

Product thickness: 0.45 mm

Coating: Gloos

Producing : ROOFER

Guarantee: 10 years

..

Product thickness: 0.45 mm

Coating: Gloos

Producing : ROOFER

Guarantee: 10 years

..

Product thickness: 0.45 mm

Coating: Gloos

Producing : BILKA

Guarantee: 10 years

..

Product thickness: 0.45 mm

Coating: Gloos

Producing : BILKA

Guarantee: 10 years

..

Product thickness: 0.45 mm

Coating: Gloos

Producing : BILKA

Guarantee: 10 years

..

Product thickness: 0.45 mm

Coating: Gloos

Producing : BILKA

Guarantee: 10 years

..

Product thickness: 0.45 mm

Coating: Gloos

Producing : BILKA

Guarantee: 10 years

..

Product thickness: 0,45 mm

Coating: Gloss

Producing : ROOFER

Guarantee: 10 years

..

Product thickness: 0.45 mm

Coating: Gloos

Producing : BILKA

Guarantee: 10 years

..

Product thickness: 0.45 mm

Coating: Gloos

Producing : BILKA

Guarantee: 10 years

..

Product thickness: 1 mm

Coating: Gloos

Producing : BILKA

Guarantee: 10 years

..

Product thickness: 0,45 mm

Coating: Wood

Size: 1,25*2,00 m

..

Product thickness: 0,5 mm

Coating: Grande Mat

Size: 1,25*2,00 m

..

Product thickness: 0,4 mm

Coating: Glossy polyester

Size: 1,25*2,00 m

..

Coating: Matný polyester

Unit of measure: m2

Size: 1,25*2,00 m

Fixing clamps for bent sheet metal...

Manufacturer: BILKA

Fixing clamps for bent sheet metal...

Manufacturer: BILKA

..

Producing : BILKA

Fixing clamps for bent sheet metal...

Manufacturer: BILKA

Fixing clamps for bent sheet metal...

Manufacturer: BILKA

It is used for the installation of folded sheet metal roofing and Retro Panel roofing.It is an anti-condensation foil that has sound insulation properties and also ensures roof ventilation...

Package size: per roll is 37.5 m2

Density g/sq.m: 300 g/m²

It is used for the installation of folded sheet metal roofing and Retro Panel roofing. The separation layer between the sheet metal and the roofing is designed to reduce noise and ensure ventilation...

Package size: per roll is 37.5 m2

Density g/sq.m: 300 g/m²

Standing seam roof details

Folded roof coverings are made of smooth sheets that are joined by a special seam. A professionally made shingle roof can last more than 100 years. Sheets for this roof are made from a variety of materials, including copper, galvanized steel, aluminum or zinc-titanium alloys. In order to fully understand the concept of folded roofs and its variants, it is necessary to familiarize yourself in detail with the properties of each type of metal.

- Galvanized steel. Galvanized steel creates corrugated iron roofs, which are characterized by a sufficiently low price and lightness (only 5-6 kg per square meter). Aesthetically, galvanized sheet usually lags behind and is often used primarily for industrial buildings such as sheds and warehouses. However, modern times have brought innovation where manufacturers now offer polymer coatings in a variety of colors and systems that facilitate installation without the need for special seaming machines. In appearance, galvanized steel with a polymer coating does not have to lag behind metal tiles. For example, the manufacturer Bilka has 12 different colors and 3 different surface treatments. The paint warranty ranges from 10 to 30 years, depending on the specific coating.

- Aluminum and zinc-titanium sheets. Aluminum and zinc-titanium sheets are innovative materials for the construction of folded roofs. These materials are highly resistant to corrosion and at the same time very light. A corrugated aluminum or zinc-titanium composite roof provides durability at an affordable price. Their service life reaches more than 75 years, bringing them closer to folded copper roofs.

- Copper sheets. A corrugated copper roof is the best you can choose! The folded copper roof is beautiful and aesthetic, while the material is soft and easy to bend, which allows the realization of complex roofs with large radii. If this work is done by professionals, such a roof will serve you without problems for more than 100 years. The only minus of such a roof is the high price of the material.

One of the main advantages of folded coverings is the absence of connecting elements. The hidden seam not only makes the roof more beautiful, but also increases its reliability.

Pros and cons of Seam roofing

The roof is the crown of every home, it protects its supporting structures from the effects of the weather. In addition, the roof has an equally important role - aesthetic! The roof gives your home an identity and underlines its style. The more complex the roof, the more attention you should pay to the choice of material.

Standing seam roofing made of copper or steel are irreplaceable roof coverings for non-standard roof shapes. This type of roofing material has high waterproofing efficiency and can be used for both flat and radial roofs.

Which standing seam metal roofing to choose?

Strip roofing with a cavity system for simple snapping of strips has a very wide range of applications, especially on roofs. Fasteners can be made with hand tools or with the help of an electric machine. Making a joint by hand takes a lot of time, and the person doing it must be experienced. Manual execution is justified only in complex places where it is not possible to use a machine.

If your roof has a one-, two- or four-pitch shape without radii, you can use the klikfalz seam. The ends of the sheets are provided with two blunt seams, which are snapped together in factory conditions. These gusset seams are equipped with teeth that click when pressed from above (hence the name click system). Covering with a click mechanism is offered by Bilka, but also by other manufacturers. Due to the simplicity of installation, low costs and the wide availability of different colors, this roofing material successfully competes with folded coverings. It is not possible to say unequivocally which of these two materials is better - the choice should be made according to the specifications of the roof structure, budget and individual preferences.

Standing seam metal roof installation

The distance between the lamellas of the double grid depends on the thickness of the metal and the dimensions. Steel panels with a thickness of 0.5 mm can be installed on a wooden grid with a distance between the slats of 20 cm, but the best solution would be to install them on a flat surface made of planks or wood. The minimum pitch of the roof when using a snap seam is 8 degrees.

Laminated coverings do not have many disadvantages. The main disadvantage is the high thermal conductivity of the metal and the noise created by hail or rain. This problem can be easily solved by using a special sound-absorbing membrane or by using a larger amount of stone wool (15 cm) for insulation.

If you need help with the installation of a standing seam metal roof, we will be happy to help you. Call us +420774592876 or +420720380592 to discuss details.

-90x90.webp)