The profiled sheet achieved its popularity with the help of its versatility, which is quite important in modern construction. The main purpose is the construction and reconstruction of industrial and residential buildings, equipment for temporary premises and retail outlets. The material is divided into categories corresponding to the types of work, according to strength and type (wall, roofing, load-bearing). Due to the unique multilayer structure, heavy rainfall, severe frosts will not affect the protective functions and aesthetic appearance. Profiling reduces the weight of the sheets and gives additional rigidity. Installation of corrugated board, transportation to the site is easy to perform without outside help.

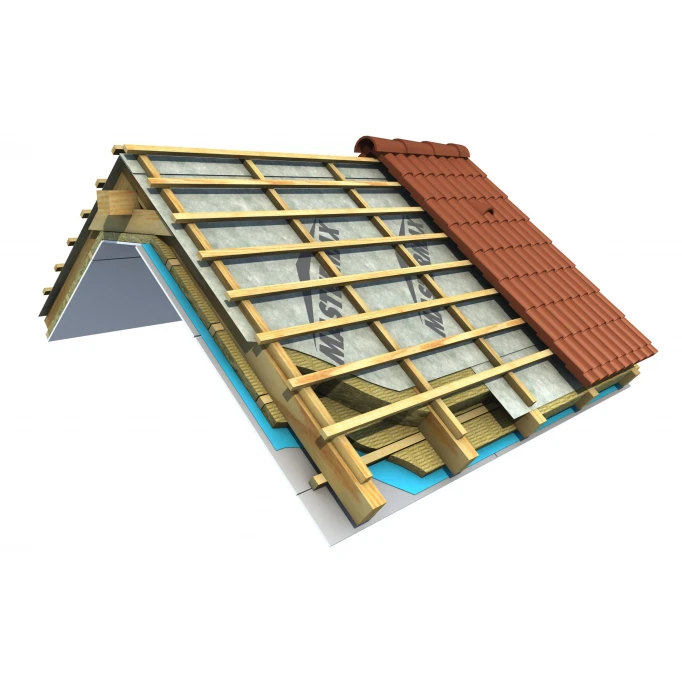

When ordering roofing from corrugated board, when choosing a product, you need to focus on the thickness of the steel - it should be from 0.45 to 1 mm. Roofing from corrugated board differs from metal tiles in that it can be used for roofs with a slope of 6 degrees. Already knowing the dimensions, you can choose the best product in terms of characteristics in the desired color design. The crate under the roof is calculated according to the load table, it depends on the height of the profile. Installation of corrugated board starts from the end of the roof, the sheets are overlapped. Screws, sealing tape are used as fastening. Roofing from corrugated board should be equipped with additional hydro and vapor barrier to increase the service life of wooden structures. Insulation is also necessary to create an optimal microclimate and, accordingly, save on heating and cooling the room.

For a private house or summer cottage, the installation of corrugated board as a fence will become not only a protective, but also a decorative element. To install the fence, metal poles of the required thickness are selected (usually a thickness of 2-3 mm is sufficient). The pillars are concreted into the ground, guides are welded to them. Installation of corrugated board consists of fixing it with screws of a suitable type or rivets to the longitudinal guides.

This is a fairly unpretentious building material in maintenance, it belongs to the category of coatings that you can install and forget about them. However, in order to extend the life of the fence, partitions, corrugated roofing and the building itself, a number of installation and further use rules must be observed. It is very important to use special tools for cutting sheets to avoid deformation of the metal. In particular, cutting with a grinder is not recommended, due to damage to the coating with this method of cutting. The screws should not be tightened too much to prevent dents in the sheet. The appearance of scratches on the coating does not affect the protective functions of the material, but it is better to paint over them with an identical color spray paint.

-90x90.webp)